+39 0124 818001 customerservice@ufs.it

Design, R&D, Production, Sales and After Sales

Almost 80 years of experience entirely in the threading tools sector

Technical evolutions and organizational innovations are bringing UFS up against major global competitors in the tooling industry such as tapping taps.

Evolution and production expansions, new research departments, metrology labs and the use of state-of-the-art computational structural calculation systems are part of the evolution; the future will see product innovations.

0

catalog codes

0

tools produced in a year

0

standard taps

0

special taps

Professional Skills

Immediate answers to facilitate your business our key performance indexes..

Product deliveries to the customer within 24/48 hours:99%

Availability of standard tools in stock:96%

Production of special products in 8/10 weeks:75%

Technical customer support:100%

+39 0124 818001 - int 238

B2B

Even Faster

The online platform aimed at professionals. With a simple request for accreditation, the UFS Customer Service will configure and send the access credentials.

# check availability of products in stock

# search for products by technical features

# immediate cart and delivery within 24/48 hours

# check availability of products in stock

# search for products by technical features

# immediate cart and delivery within 24/48 hours

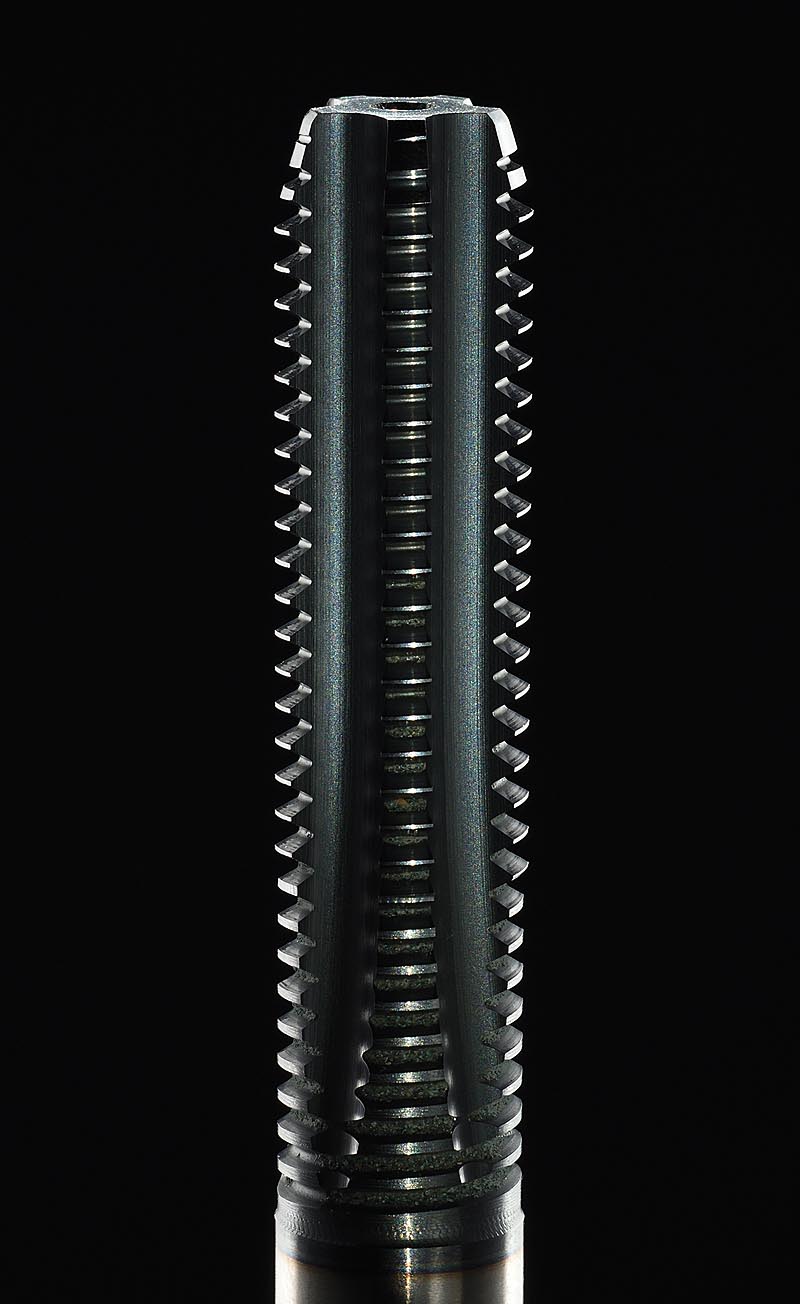

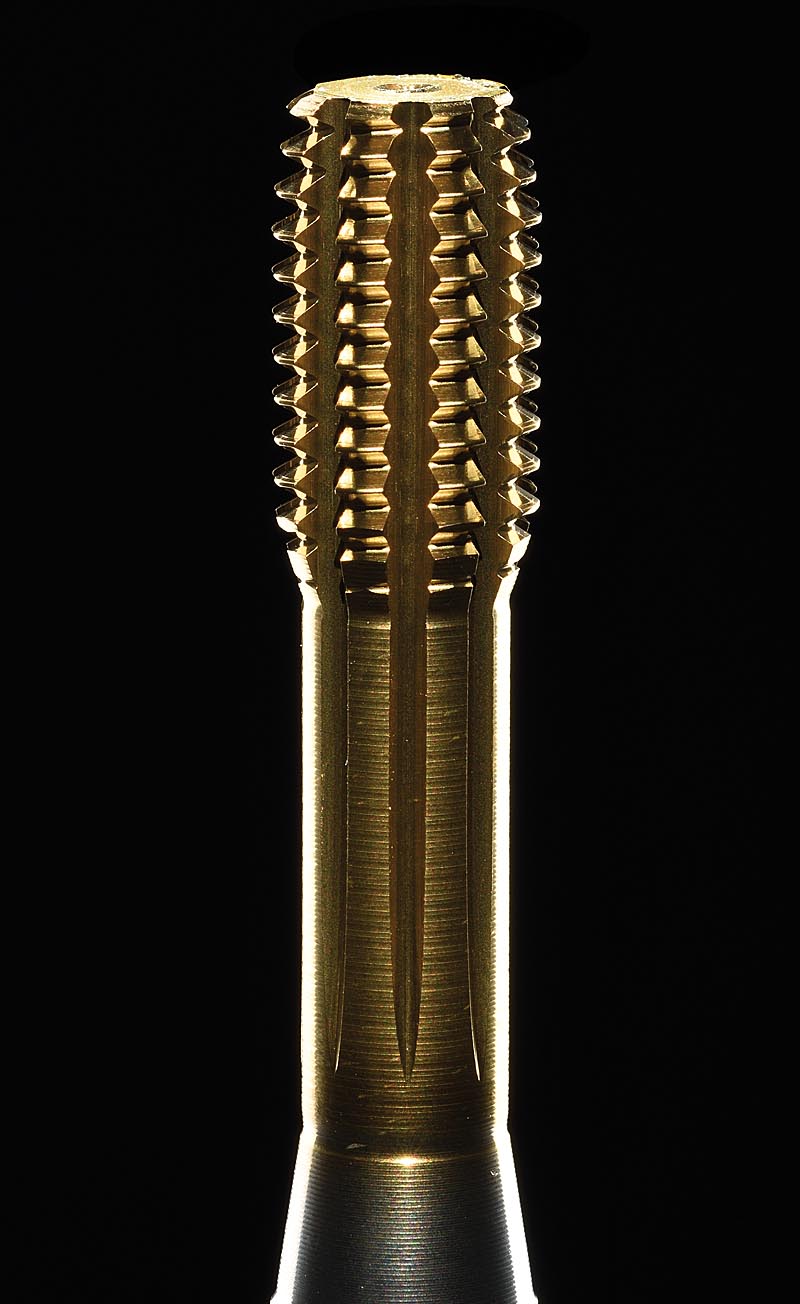

The LINE with HSSE steel tools, the PLUS with the use of steels with a higher cobalt content, the S-PLUS for tough steels and with latest generation finishes combined with TiN-G coatings and the TOP which represents the spearhead of the UFS production with tools designed for the processing of specific materials, including powdersintered steels, and with plasma coatings (PVD).

# 5000 codes with minimum diameter 2mm

# 26 thread Families

# removal and deformation taps

# 5000 codes with minimum diameter 2mm

# 26 thread Families

# removal and deformation taps

Products

Cutting taps, forming taps, plugs and dies with thread control and calibration tools

# the UFS standard taps covers many international standards (DIN,ISO, JIS.. standards)

# also supplies products for specialized supply chain

# it manufactures on request many special taps with tolerances or according to the Customer Specific Requirements

R&D

Research and Development, always fundamental

The R&D department, today expanded and complete with latest generation equipment and technologies, it is based in Site 2.

# 3 metrology laboratories

# metallographic, dimensional, surface and coating analyses

# collaborations with international universities

# 3 metrology laboratories

# metallographic, dimensional, surface and coating analyses

# collaborations with international universities

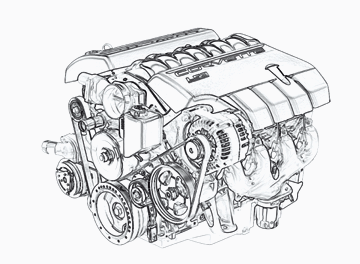

Special Applications

All Made in UFS

Reliefs, tolerances and coatings for specific applications. A continuous evolution of the materials to be machined.

Contact Customer Service for any threading needs.

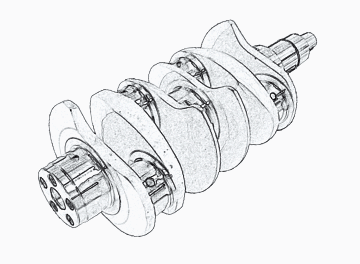

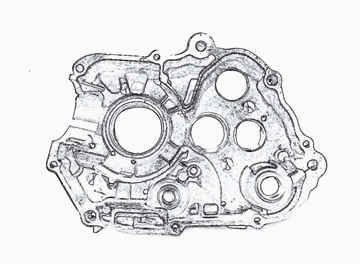

horizontal thread of crankshafts...

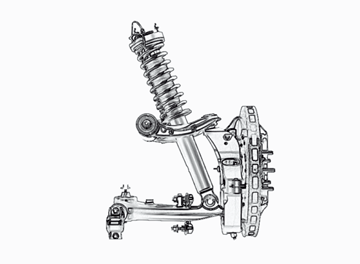

threading of aluminum castings for the automotive industry...

connecting rod thread, precision and fatigue resistance of the connecting rod...

thread for specific applications for the wind power sector...

threads for right and left pedals and dropout...

nut threading; in different tolerance modes, available with the screw connection...

thread of the tie rod which constitutes the "third point"...

In addition to the offices, Site 1 also houses the production of standard and special tools.

Site 2 houses theResearch and Development department and all PVD coatings are carried out.

Site 3 carries out the blanks with the turning shop and hardening ovens and discovery.

Site 2 houses theResearch and Development department and all PVD coatings are carried out.

Site 3 carries out the blanks with the turning shop and hardening ovens and discovery.

3 Productive sites

When the territory and its community represent essential values

Filettonews

Filetto, the UFS mascot

Designed years ago by the hand of the General Director, it is a lucky charm that UFS has chosen to represent itself. Follow Filetto to be constantly informed about news from the world of threading.

Sign up for free to periodically receive Filettonews.

Social Media

Virtual meeting places and discussion forums

Communicate more easily and quickly, guarantee immediate feedback and provide advice and information to the audience of threading enthusiasts. Follow them!